However well you plan your installation, fiber cable is rarely the right length for each run, and is inherently difficult to join. Consequently, cables have to be connected or cut in the field, with the potential issues this entails. This blog post looks at the various options available to installers for responding to these issues; from splicing and field-fit connectors to factory-terminated or pre-connectorization.

1. Splicing in the Field

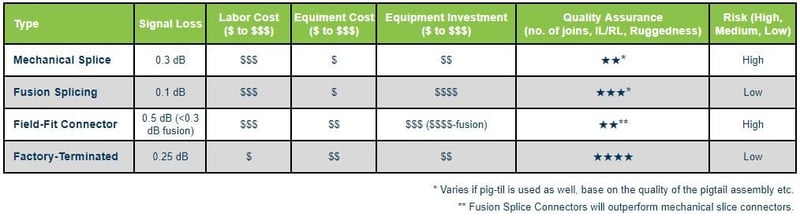

When fiber was first deployed, it was mechanically spliced, meaning that fibers were butted together as tightly as possible and then mechanically encapsulated. Due to the potential for signal loss and poor reliability this was soon superseded by fusion splicing. This offers the best quality connection of all in-field options in that the fiber ends are lined up and welded together. No excess cable is left over when the process is complete.

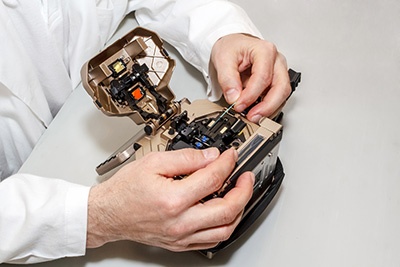

However, fusion splicing is time-consuming and requires specialist labor and equipment. There is no guarantee that the splice will be successful until it is completed. Availability of specialist splice engineers can be a big problem - those that can be obtained on the open market often charge high rates. In many developing countries, trained splicers and jointers are in such short supply that it is unfeasible to use them for a project of any size. However, for the very largest telcos who have invested heavily in training and equipment fusion splicing, field-termination can make financial sense.

2. Field-Fit Connectors

In the 1980s, connectors with ceramic ferrules were invented by NTT in Japan and then developed by a range of companies. These connectors are mechanically attached to each end of the fiber, in the field.

As they add a third component (the connector) to the two fibers it does add an additional point of signal loss, that can push the installation below acceptable tolerances. As with any field-fitted component there is the possibility of failures caused by water or dirt entering the connection, while changes in temperature can affect their longevity. However, they do offer a cheaper solution than splicing, requiring less skilled staff and lower investment in equipment.

3. Pre-Connectorized or Factory-Terminated

Factory-terminated fiber cable comes direct from the manufacturer, where it is prepared under the supervision of fiber optic experts in a high care, clean environment, free of the dust and other pollutants found in a common field environment.

All completed assemblies are tested through each connector to the stub end of the fiber, with documentation being provided as a deliverable item for each and every assembly. Different grades of factory-terminated cable are available, dependent on quality needs.

When working with fiber, relying on factory-terminated/pre-connectorized cables offers several advantages over field termination, including both performance and savings in labor, material costs and installation time. The technology also increases network reliability as quality is guaranteed by the manufacturer.

4. Pre-Connectorization and Field-Fit/Splicing

Factory-terminated cable does deliver clear advantages in lower labor costs, higher performance and faster implementations. However, taking advantage of factory-terminated cable requires some forethought and planning. Knowing where panels must be located and the length of runs from the panel to various pieces of equipment is necessary.

The downside of fully pre-terminated cable is that there is almost always excess cable left over from installations. This excess cable has to be coiled up in a storage box on the premise, or housed in a facility beside the curb, which can be unsightly.

As an alternative some operators are looking at a half and half solution, with a pre-terminated connector on one end and a splice or field-fit connector on the other. This means that little fiber is wasted when mechanical connectors are used and the equipment required is relatively inexpensive. There is no need to invest in boxes to store the excess cable, reducing costs. However, semi-skilled personnel are still needed to do the job and the mechanical connectors are twice as expensive as standard connectors. Lastly, the losses are relatively high.

The Factors to Consider When Making a Choice

Staff Skills

80% of costs for an FTTP deployment goes on labor. Removing the need to field-fit connectors, means that lower skilled labor is required, making it a more economical solution than field termination of fiber cables. Obviously, if you have ready access to staff trained in fusion splicing that will provide a different option to consider instead of factory-termination.

Rework and Equipment Costs

Not only do factory-terminated cables eliminate the labor costs associated with installing connectors in the field, but they also avoid the need to spend time and money on re-doing work that has failed, and the cost of additional connectors. Common figures cited by service providers are capital savings in the range of 40-50% as there is no need for specialist equipment. Again, for those telcos that have invested in fiber splicing machinery, it may be cheaper to use this rather than buy factory-terminated cables.

Installation Time

Even more significantly, pre-connectorization provides a reduction in installation time of over 60-80% - when compared to traditional installation methods. For example, the City of Loma Linda in California lowered deployment costs on the last mile of its FTTP network by between 64-76%, through a combination of using factory-terminated pushable cable assemblies and micro-trenching.

The alternatives for connecting fiber offer different advantages dependent on an operator’s existing equipment and the skill levels of its staff. It is therefore vital to balance cost and reliability, not just for the deployment but over the entire life of the installation, when choosing the best method for individual needs.

Comments