We’re sorry! Our webpage is not compatible with your browser. Please update your web browser for full functionality of this page

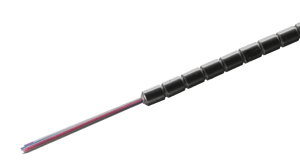

Fiber,

Miniflex® technology, 1-24 fibers, anti-kink design, flexible, UV stable, lightweight, compact, high crush resistance, flame retardant

Our monthly newsletter is the best way to keep up to date on all things PPC

Sign upCopyright 2024 - PPC Broadband, Inc. | Terms and Conditions | Privacy Policy | Patents