In our series of blogs based on PPC’s Complete Guide to Fiber to the Premises (FTTP) Deployment eBook, we’ve outlined the options for operators, when it comes to:

In our series of blogs based on PPC’s Complete Guide to Fiber to the Premises (FTTP) Deployment eBook, we’ve outlined the options for operators, when it comes to:

- Picking a fiber architecture (PON or P2P)

- Choosing between aerial and buried deployments

- The labor costs of FTTP deployments

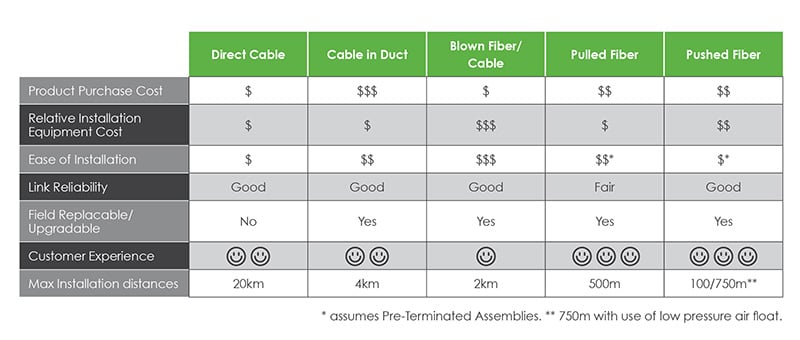

The 5 last drop fiber installation methods

Moving on, operators then have to choose the installation method for the last drop of their FTTP network. Based on our experience, here are the pros and cons of the main techniques, along with some more detailed analysis:

1. Direct cable

Cable laid directly from the last node to the customer is at first sight the obvious solution. It is a simple item to purchase and there are no compatibility issues in acquiring a matching duct.

However, there are important concerns that may mitigate against this option. Direct cable cannot be easily upgraded, since excavation or access to aerial infrastructure is required, which can necessitate specialized equipment. Direct buried cable can be damaged from subsequent digging activity and is difficult to repair, leading to potential signal degradation.

Additionally, while direct cable is designed to typically last 25 years,the effective lifetime of the optical fiber itself before it becomes obsolete may be considerably less. Consequently it is not a future-proof cable solution for operators.

2. Cable pre-installed in duct

Cable pre-installed in duct provides greater protection from accidental damage than buried cable and can also be replaced relatively easily.

One of the downsides of this option is that it limits operators to particular types of fiber. This may not be an issue for an operator that wants to install fiber in a planned build but does not allow fiber replacement on an ongoing basis.

There are other disadvantages - it generally costs more to purchase cable pre-installed in duct than the two products separately. Operators may be left with an expensive asset sitting in the ground if there isn’t sufficient customer take up while if the wrong type or amount of cable and duct are purchased, the operator runs the risk of ending up with a sizeable amount of redundant stock.

3. Blown cable/fiber

A considerable proportion of fiber is installed by blowing. The technique involves using compressed air to blow a fiber or a cable down a small duct. Blowing fiber is popular because it is a fast process, and the blown fiber can be installed over great distances.

Blown cable, on the other hand, is a more robust option. However, these cables are significantly larger and more expensive to both purchase and install and require larger blowing machines. Blowing distance is directly related to weight of cable, friction from duct liner, and pressure used.

There are a number of downsides to using blown installation. The process can be costly – specialist equipment and labor are needed to blow the product. It can also cause considerable inconvenience to the customer, with soil and water occasionally blown into the customer’s premise during the installation process. As blowing is designed for long distances, it can be economically inefficient for the operator if multiple short-runs are involved. Set up and tear down times can frequently exceed the amount of time allocated to blowing.

4. Pullable cable

Cable can also be pulled along a duct infrastructure, which is a cost efficient option because it requires no extra equipment. It is also suitable for installing short lengths of fiber cable, which makes it perfect for the last drop. However, pulling is a labor-intensive practice with two people needed to deploy the cable.

There are additional difficulties that come with pulling. As route length increases, the force required to pull the cable increases which results in increased tension in the cable - once the manufacturer specified pull force is exceeded there is a danger of damaging the optical fibers themselves. Given these potential problems it is therefore advisable for operators to use trusted and skilled personnel to carry out cable pulling.

5. Pushable cable

Fiber cable can be pushed either manually or using suitable equipment from the premise to the cabinet. The technique causes minimum disruption to the consumer.

Pushable fiber can also save substantially on labor costs. When used with a preterminated pushable connector on one end and an industry standard connector on the other, all splicing and termination labor can be eliminated. Installing the cable itself is very straightforward. It can be done with one person pushing by hand or with the help of an inexpensive, simple machine – again saving on labor costs. Pushing cable by hand alone can be used for distances up to 100 meters (328ft).

Should a fiber be cut or damaged, the pushable fiber can be located and pulled from the duct – and it serves as a ‘tape measure’ so that the distance required for a replacement product is easily calculated.

Not all operators will choose to use preterminated pushable cable. With a pushable pre-connectorized solution there is bound to be excess cable. This cable can either be coiled up in the cabinet or stored in a box on the customer’s premise. While the second option may be aesthetically unpleasing, it is a relatively easy operation to carry out.

There are downsides to using pushable cable, which are worth mentioning. The cable tends to be expensive when compared to other options. At present, a large duct is also needed to carry pushable fiber into a premise, which can add to material costs.

Making FTTP deployments cost-effective

Installing a FTTP network is no mean feat. Operators have to consider a bewildering range of choices. They need to determine whether it makes commercial sense to install a network in the first place. Then they have to factor in other elements like cost of labor, landscape and customer experience. Each choice will inevitably lead down a particular route and entail other critical choices. But if all of these factors are taken into account and are critically assessed, there is no reason why an operator cannot install a FTTP network practically anywhere in the world and get commercial value from it.

To find out more, download the m2fx eBook on FTTP deployments, which outlines the full range of options for operators looking at this area.

Comments