Category cable is one of the most widely used cables for domestic and commercial broadband networking. Whether you are installing access points, network interfaces, or security systems, category cable is going to be part of what you will need.

We know what you are thinking – category cable is all the same, right? Not exactly.

There are actually several factors to consider when choosing the right cable. Here we will discuss 5 details to look for when buying category cable.

Before we can do that, we need to decide which level category cable we will need.

The two types most commonly used are Category 5e and Category 6 cables. Both are made from 4 pairs of twisted conductors housed in a polymer jacket. CAT5e can provide 1 Gbps speeds up to 100m (328ft), while CAT6 can provide 10Gbps speeds up to 50m (164ft) and 1Gbps speeds up to 100m (328ft). Additionally, CAT6 has greater crosstalk performance due to its larger gauge and increased twisting. This leads to fewer errors and lost packets compared to the same length of CAT5e cable.

Determining Quality Category Cable

An overlooked aspect of category cable that may have a big impact on the ease and speed of installation is how easy it is, or is not, to put a connector on the cable. If you ask an experienced installer whether they have ever needed to redo a connector on a category cable, you are likely to hear a story about a very frustrating experience and a costly learning curve.

An overlooked aspect of category cable that may have a big impact on the ease and speed of installation is how easy it is, or is not, to put a connector on the cable. If you ask an experienced installer whether they have ever needed to redo a connector on a category cable, you are likely to hear a story about a very frustrating experience and a costly learning curve.

When researching category cable, look at small details like: the number of twists per inch on each pair, how bright the colors are for each wire, how thick the outer jacket of the cable is and the shape/size of the core separator (if present). These may seem like minor details, but the smallest element can make a difference in this field. Putting on a connector quickly and easily – once – can eliminate many minutes struggling with re-terminating.

Top 5 Factors to Consider when Choosing Category Cable

1. How Many Twists?

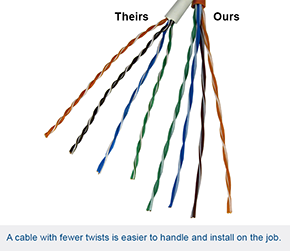

A category cable with twisted pairs that have more, tighter twists is going to be difficult for a technician to handle and install on the job. The more twists, the higher the chance of misaligning the wires when installing a connector.

technician to handle and install on the job. The more twists, the higher the chance of misaligning the wires when installing a connector.

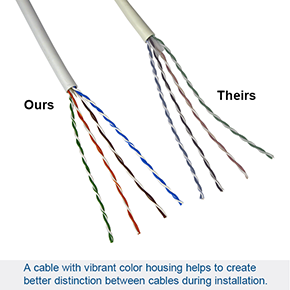

The best cable has fewer twists while still maintaining full performance per ANSI/TIA/EIA-568-C.2. Some low-cost wires will use a technique known as hyper twisting in order to overcome lower quality insulation and conductors. This can be seen in the above comparison of two seemingly identical CAT5e cables.

2. Cable Housing Color

The color of the cable housing may not sound like a big deal, but how many times have you installed cabling in a dimly lit basement or room? Brown and orange, or green and blue can look pretty similar in poor light.

Find a cable with vibrant and distinct colors, and you will not mistakenly order the pairs in a connector again.

3. Cable Jacket Thickness

The cable jacket is often overlooked when purchasing category wire, however it can have a big effect on connectorization. A thinner jacket with a standard outer diameter gives the twisted pairs more room to move and flex during installation, which leads to pair separation and performance degradation. It also makes it easy to inadvertently cut the conductors.

A thicker jacket with a standard diameter will protect the conductors from over-flexing and unintentional cuts. In addition to these ease of installation considerations, the jacket material must also meet NEC, UL and local codes for UV exposure, flame resistance and more. It is important to carefully evaluate the type of jacket when deciding which cables to purchase because no one jacket material will meet all needs.

4. Core Separator Considerations

With CAT6 becoming prevalent in the field, installers are running into more core separators (commonly used in CAT6 to enhance performance). Lower-cost cables may use a thick star-shaped separator as a method of enhancing crosstalk performance. These thicker separators can be hard to remove and will increase installation time.

A quality cable will instead use a thin separator that can be removed easily during installation.

5. Avoid Copper-Clad Aluminum

Finally, be aware of copper-clad aluminum (CCA) cable. This low-cost option can seem like the perfect deal, but it will actually introduce several issues during installation and operation. CCA cable is highly prone to broken conductor breakage when flexing during installation and use.

Another issue with CCA is its higher electrical resistance compared to copper, which can cause trouble with Power-over-Ethernet (PoE) applications. Greater resistance results in more heating of the cable and reduced power available at the PoE device.

Satisfy The Customer

Different brands of category cable may look similar on the outside, but the biggest difference is in the details. When category cable is made right, it will create ease and efficiency for the technicians. When technicians can save time during installation and provide better service due to the parts used, the customer will be highly satisfied.