Closures are the housings which contain and protect the individual joints in any fiber system, as opposed to fiber joining (fusion splicing, connectorization and mechanical splicing), which are covered in this separate blog. Given how fragile fiber is, and the potential need to upgrade cables, good quality closures are vital to a successful installation. But what is a closure and what should you be looking for when choosing one?

Closures are the housings which contain and protect the individual joints in any fiber system, as opposed to fiber joining (fusion splicing, connectorization and mechanical splicing), which are covered in this separate blog. Given how fragile fiber is, and the potential need to upgrade cables, good quality closures are vital to a successful installation. But what is a closure and what should you be looking for when choosing one?

Types of closures

Basic Closures

At its simplest, a closure joins one length of fiber cable to a different length of the same type of cable. This is sometimes known as in-line closure or track joint. Added functionality is provided by a spur (or branch) joint which divides the cable into two ongoing parts - the main cable and a side or spur cable. There are also end of route closures where the cable is broken out into individual elements for customer or telco connection.

The earliest fiber closures were direct descendants of their copper cousins. The simplest in construction (but not to use!) were wrap-around heat-shrink products, most usually just in-line closures but sometimes branch joints. Although they could be made water resistant they had few other benefits (except low cost) and often required a skilled jointer to apply them.

Tube Distribution Closures

With the widespread adoption of blown fiber and cable systems which use multiple microduct bundles, tube distribution closures have become prevalent. As the name suggests these either create an in-line microduct track joint or, more commonly, branch off individual microducts to different destinations. Instead of fiber jointing occurring in the closure, individual microducts are joined together by purpose-made push fit connectors that in themselves are designed to be water tight. This has enabled the closure to be of simple design, without the need for expensive seals and is easily assembled in the field.

Dome Closures

Probably the most common type of closure is now the ‘dome’ closure, which comprises a base with cable port inlets, a stack of splice trays and a removable dome cover. The advantages are:

Probably the most common type of closure is now the ‘dome’ closure, which comprises a base with cable port inlets, a stack of splice trays and a removable dome cover. The advantages are:

- The format is easily sealed to IP68, yet the dome can be removed in seconds for re-entry.

- Many configurations of base can be produced within the same overall footprint

- By using different domes closures can be expanded to add in more splice trays.

However, having a robust outer casing is only half the challenge. The other 50% is to contain and organize the fiber-to-fiber jointing function. In general, optical fiber cables are comprised of cable ‘elements’ (commonly loose tubes or ribbons). So a 144 fiber cable comprises twelve 12-fiber ribbons or twelve 12-fiber loose tubes. A ‘single element’ splice tray therefore houses an entire cable element’s worth of fibers. This arrangement is well suited to in-line (track) closures. The fibers are stored for long term survivability with no expectation that the closure is an intentional point of intervention. However, for branch (spur) there is often the intention to go back to the closure repeatedly to add, subtract or re-route individual circuits. Then it is beneficial to store a ‘single circuit’ on one splice tray. Using this approach individual customers can be connected without disturbing existing circuits.

What to look for in fiber closures:

More modern closures take into account these four key requirements:

More modern closures take into account these four key requirements:

- Suitable mechanical and environmental properties – such as impact resistance, crush resistance, vibration rating and temperature and fluid resistance

- Attention to sealing performance. Both the closure body must seal to its rating and also to cable port(s). The cable ports must also withstand relevant tensile loads imposed by direct movement or thermal effects from cable shrink-back. Note that closures do not necessarily need to be ‘fully’ waterproofed (IP 68 rating) but depending on their use can be rated to a lower level such as IP 67.

- Re-entry. Some closures can be safely sealed shut and forgotten about. However the majority need to be re-entered to either add/delete customers, upgrade the fiber, or as part of fault repair. This has led to advances in cold-sealing technology using rubber seals, gaskets and gel compounds

- Mounting requirements. Closures need to be secure sited. This means safely placed in an underground chamber, attached securely to an aerial cable support or installed with aesthetic consideration in a customer’s building.

Trends in Closures

The themes of easy-closing, safe access to fibers, environmental hardness and flexibility are likely to persist. G.657 fibers with safe bend radii smaller than 30mm have led to splice trays with a tighter storage radius. Mass splicing for ribbon means splice trays need now to store mass-fusion splice holders.

But perhaps the greatest changes will continue to be in the customer’s building. Given aesthetic concerns, small, electrical socket type boxes, flush or surface fitting and with a high quality decorative finish, are now essential. These should be able to accommodate incoming pre-terminated or plain fiber for connector, mechanical or fusion jointing to patch cords connecting the customer’s equipment to the network. In some cases, especially with PONs, these closures may need to house removable wavelength filters (for instance Bragg Gratings). In fact with the advent of WDM-PONs that location will become an important demarcation point.

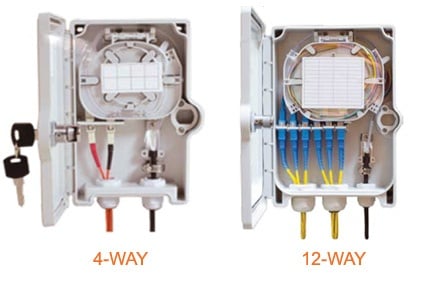

In some regions, especially North America, the customer connection closure may be sited externally or in sheltered position (such as a building porch). These units therefore need to accomplish all the function above plus substantial weather-proofing.

Fiber closures are a key part of any deployment – installers therefore need to pick the right type for their environment if they are to deliver a long-lasting solution that meets their requirements and doesn’t spoil the end-customer’s décor.