With its products used in thousands of fiber deployments across the globe, Dura-Line is one of the world’s leading suppliers of conduit duct. Installers know and rely on Dura-Line when it comes to ease of deployment, effectiveness and reliability.

Given its market leading position, we wanted to test how the combination of PPC's patented Miniflex fiber cable and Dura-Line’s duct performed together. To do this we worked with Dura-Line and a major local telephone company in the US on out a joint Fiber to the Premises (FTTP) installation to a strip mall in Louisiana. The aim was to measure the compatibility of the two products and to see if the combination improved deployment performance for the installation crew.

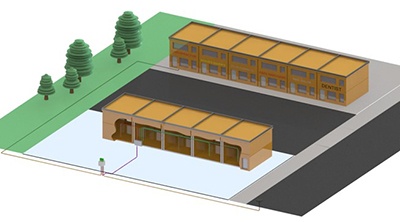

The trial took place at two, separate, single level buildings, one with five individual business units and the other with six. The infrastructure comprised two customer-owned PVC conduits (2 inch and 1¼ inch) running from the inside utility/comms rooms (one per business unit) to the utility box on the outside of each building. In turn this was connected to the hand hole splice box in the street via a feeder cable.

For the installations the 1¼ inch conduit was used, with Dura-Line placing their duct into the conduit. Once it was installed, PPC's cable was then pushed or pulled by hand or machine to complete the deployment. All installations were completed by the customer’s crew, with minimal intervention from PPC or Dura-Line.

Cable lengths in each building ranged between 100-300 feet, with two 90 degree bends in each installation. Dura-Line microducts (10/8mm for building #1 and 12.7/10mm for building #2) were used, combined with the fiber cable, pre-connectorized at one end. The fiber cable in building #1 was pushed by hand, with building #2 installed with a Condux machine, solely with a push-drive belt, rather than blowing air.

100% compatibility, shorter deployment times

The crew started pulling duct through building #1 at 9.30am, with the job finished by 11.50am. The first two units in building #2 were completed on the same day. It took between 10-15 minutes per unit to install the Dura-Line duct, while PPC cable installation time ran from 3-6 minutes per unit, dependent on the length of the cable, using manual pushing, at an average speed of 30 feet per minute. On the longest, 300 foot, run of building #2, when the Condux machine was used, it took just 6 minutes to install the PPC cable, including a pause to place a coupler on the Dura-Line duct, which had kinked in installation.

It took between 10-15 minutes per unit to install the Dura-Line duct, while PPC cable installation time ran from 3-6 minutes per unit, dependent on the length of the cable, using manual pushing, at an average speed of 30 feet per minute. On the longest, 300 foot, run of building #2, when the Condux machine was used, it took just 6 minutes to install the PPC cable, including a pause to place a coupler on the Dura-Line duct, which had kinked in installation.What impressed the crew was how easy it was to install Dura-Line and Miniflex together. The products proved to be 100% compatible, with our cable easy to pull or push through the duct. Deployment times were reduced and, adding PPC cable to Dura-Line significantly enhanced duct performance, strengthening it without impacting lightness or flexibility. Little training was needed by the crew, who found the cable to be simple to install, whether it was being pushed, pulled or deployed with the Condux machine.

Not only were the two products completely compatible, taken together, the combination delivered a straightforward, reliable installation during our trial, shortening the deployment time and increasing the strength of the fiber connections.