Fusion splicing is often used and is appropriate for trunk portions of a network; it offers low optical and reflection loss and splicing efficiency for large fiber bundles.

Fusion splicing is often used and is appropriate for trunk portions of a network; it offers low optical and reflection loss and splicing efficiency for large fiber bundles.

When it comes to the drop network, however, with only a couple of connectors per drop, you can achieve substantial cost savings by using mechanical connections or pre-terminated fiber cables. Using fusion splicing in the drop adds time and cost.

In this post, we will examine the impracticality of fusion splicing in the last few hundred feet to the premise vs. cost savings from mechanical optical connections, and pre-terminated fibers.

Optical loss

The typical loss budgeted for a fusion splice is 0.1dB and 0.3dB for a mechanical connector. Considering that most subscriber drops will have two localized optical connections between their devices and the distribution network, using connections that install fast and with ease should be considered. It is highly unlikely that the optical loss budget in the network design will be affected by these last two connectors - because the loss in each drop is not aggregated in the distribution network, there will be negligible impact on the loss.

Splicing cost

For contractors or technicians focused on MDUs and residential applications, mechanical optical connection or pre-terminated cables are fast and less expensive. As the number of connections increase with subscriber growth in FTTx, the economies tilt toward pre-terminated cables or mechanical optical connections. Mechanical optical connections have a low initial investment but costs more per connection (<$15 each). With fusion splicing, the initial investment is much higher (>$5,000) while the cost per connection is lower.

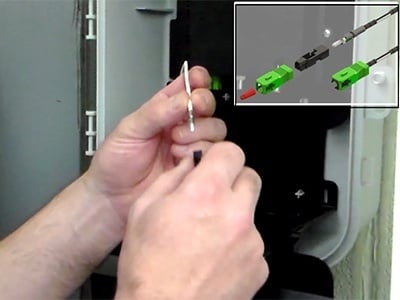

However, with a pre-terminated or mechanical optical connection, more optical drops can be done in a day. Mechanical optical connections take less than five minutes to make, while for fusion splicing you first need to set up the splicing equipment before you can begin splicing and so the process takes much longer.

However, with a pre-terminated or mechanical optical connection, more optical drops can be done in a day. Mechanical optical connections take less than five minutes to make, while for fusion splicing you first need to set up the splicing equipment before you can begin splicing and so the process takes much longer.

The wisest policy will often be to invest in fusion splicing for long-haul, trunk applications that require a separate, more specialized installation crew.

For shorter drop networks, it may be much more economical to use mechanical optical connections or pre-terminated connections that are quicker and easier to install.

Summary

80% of costs for an FTTP deployment go to labor. Using field-fit connectors means that lower skilled labor is required with less capital in equipment for crews focused on the last few hundred feet. Pre-terminated cables provide a reduction in installation time of over 60-80% - when compared to traditional installation methods. The alternatives for connecting fiber offer different advantages dependent on an operator’s existing equipment and the skill levels of its staff. It is, therefore, vital to balance cost and reliability, not just for the deployment but over the entire life of the installation, when choosing the best method for individual needs.